THE GENTLE TOUCH IN MIXING

- Established in 1963 as an engineering workshop, Lindor has evolved into a leading global provider of powder and granulate mixing, coating, and drying systems. The company specializes in the development and sale of dry product mixers.

- The Lindor engineering department uses advanced CAD systems and calculation methods to design mixers based on customer specifications. The company’s modern manufacturing facility and extensive test center, located on-site, allow for thorough mixing tests. Lindor also has testing facilities in the UK, Japan, Malaysia, and India to meet the needs of customers worldwide.

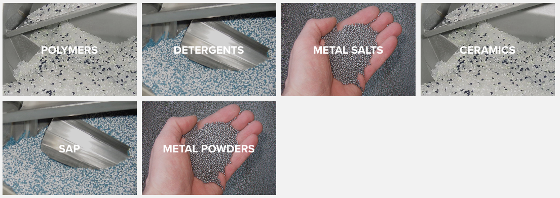

Lindor Rotary Drum Mixers Are Used To Manufacture Products Of

Lindor Industrial Chemical Mixers

Lindor’s industrial chemical mixers and processing machines provide the ability to treat a diverse range of materials with various processes in one machine. The low shear force design of Lindor’s industrial mixers makes them ideal for handling delicate or heat-sensitive products. Additionally, the ability to add liquids during the mixing process is a valuable feature for many industrial manufacturing processes.

Diverse Applications

Lindor processing machines are capable of handling a wide range of chemical products and polymers. Some common applications include polymers, compounds, ceramics for electronics or refractories, SAP (Super Adsorbent Powder) used in hygiene products, casting additives, and more. Additionally, Lindor’s mixers are well-suited for processing (highly sensitive) powders, such as detergents, battery powders, and metal powders.